The Lie We Keep Telling Ourselves: Why Construction Can’t Afford to Keep Failing the Schedule

Let’s get straight to the point. The fundamental flaw in traditional project management is that it assumes perfect order in a world defined by chaos.

When I say this in large groups, there are usually a lot of head nods. Yet, for some reason, we all simply accept it as “just the way it is.”

In theory, project management is supposed to bring discipline and structure. In practice, especially in construction, it often brings rigid optimism wrapped in a schedule that never had a fighting chance. The old playbook was built on the idea that if you set a timeline, a budget and assign resources with precision, everything will fall into place.

Spoiler alert: it rarely does.

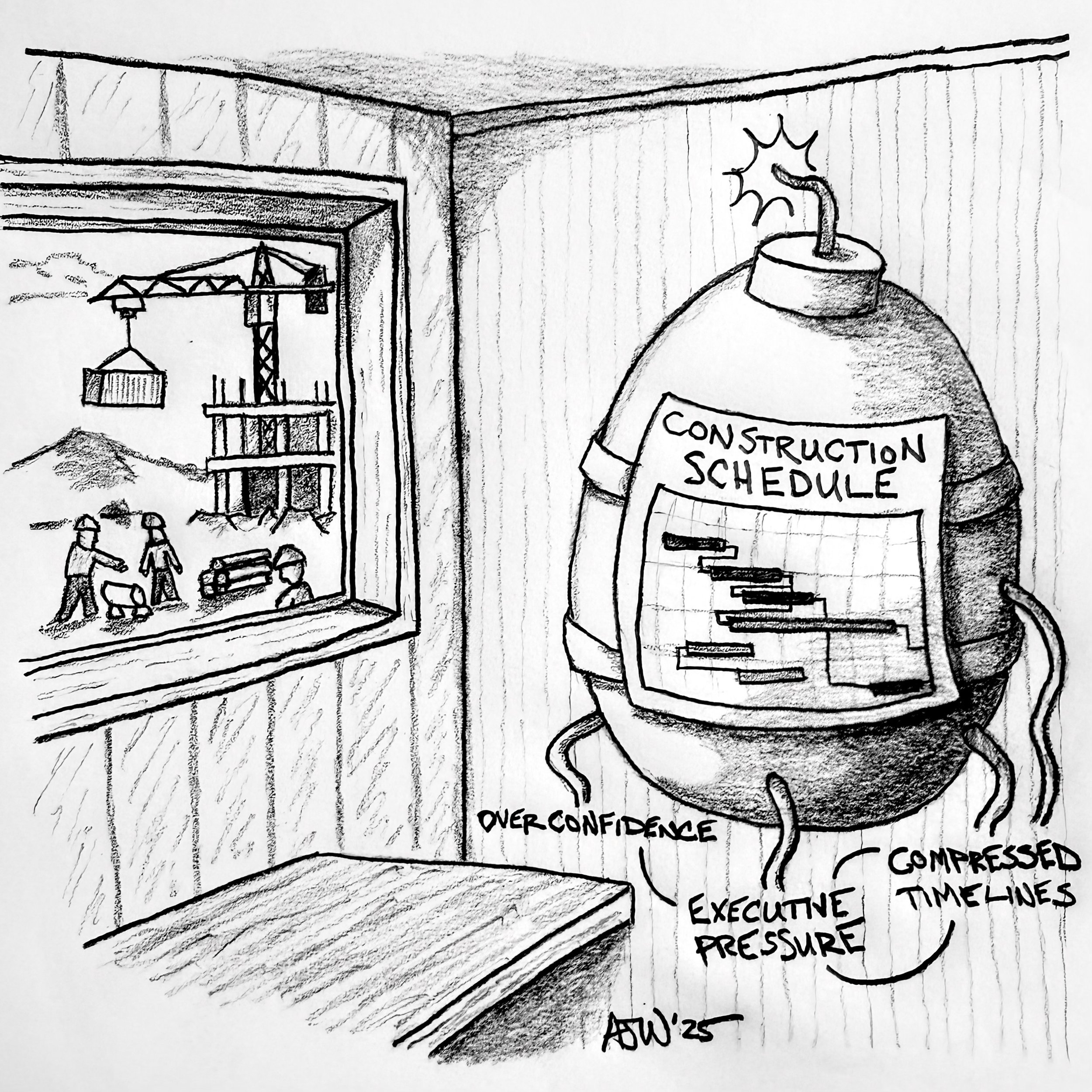

That’s because traditional project management is built on a dangerous illusion, a fallacy in planning. Construction schedules are built on our tendency to underestimate how long tasks will take and how much they’ll cost, even when we have plenty of evidence to the contrary.

The result? Most projects don't actually finish late. The original schedule was just wrong to begin with.

How Bad Planning Breaks Great Projects

In construction, we see this fallacy time and time again.

One of my favorite examples is the Sydney Opera House. Initially projected to cost $7 million and be completed in just four years, the project ultimately took fourteen years and ballooned to over $100 million. The delays stemmed from political pressure to start construction before the design was fully resolved, a lack of coordination between architect and engineers and continual design modifications during construction. Planning was based on idealistic assumptions, not grounded feasibility.

But the iconic roof was actually one of the many late design modifications. So, I guess it wasn’t all bad?

Then there’s also Boston’s Big Dig, the central tunnel project through the city. The original budget was $2.8 billion with a 1998 completion goal. Instead, it wrapped up in 2007 at a staggering $14.6 billion. Why? Well, that’s a long, complicated list including things like unanticipated geotechnical challenges, discovery of a sunken ship (no joke), contractor disputes and chronic scope creep. Once again, planners built around best-case projections without accommodating the inherent messiness of real-world execution.

These weren't execution failures. These were failures of planning assumptions from day one. The schedules weren’t blown. They were fiction to begin with.

The Planning Fallacy: Construction’s Hidden Saboteur

This so-called planning fallacy is baked into our industry. It shows up when:

We assume best-case scenarios for productivity. Labor is forecasted at peak performance, as if delays, learning curves or variable worksite conditions won’t interfere. Crews are expected to hit ideal productivity benchmarks from day one, even though those numbers are often based on controlled environments or overly optimistic historical comparisons.

We plan around ideal weather, flawless supply chains and zero design revisions. The schedule doesn’t account for rainy seasons, heatwaves, material backorders, permit delays or design changes from stakeholders. It literally assumes every dependency will show up on time and in perfect sequence. That might work in a spreadsheet. It doesn’t work on a jobsite.

We cave to pressure to make a plan look "doable" on paper. Rather than deal with pushback, planners compress timelines, slash contingencies, skip risk assessments and present numbers they know are unlikely just to win project approval. It’s not that people don’t know better, it’s that they’re forced to make the plan look clean whether the real-world path will be or not.

Even worse, as we lean on ideal past productions, we completely ignore past troubles. Every job is treated as if it's the first of its kind, even when there's a wealth of data from past projects screaming: "It won't go the way you think."

This internal bias, what Daniel Kahneman called the "inside view,” leads us to build plans based on wishful thinking instead of historical evidence. And when the inevitable surprises show up on site? We scramble. We blame. We burn out.

How to Break this Cycle

The classic definition of insanity is “doing the same thing over and over while expecting different results.” If we want to avoid insanity, we need to stop managing construction like it’s a factory assembly line and start managing it like the unpredictable, living ecosystem it is. Here's how we move from fiction to function:

1. Take the Outside View

Stop relying on your gut or your last “lucky” project. Instead, look at the real data from projects just like the one you're planning. Use that as your baseline. It's not sexy, but it’s solid. Actual-performance forecasting forces us to confront reality (you know, what actually happened on similar jobs) not what we hope will happen this time.

2. Use Probabilistic Forecasting

Throw out the single magic number and start thinking in ranges. A Monte Carlo simulation isn’t just some trick, it’s a way to plan with real odds, not optimism. Want to be confident you'll hit your schedule 80% of the time? Then stop planning like you’ll hit it 100% with no setbacks. Forecasting with probability bakes in the bumps.

3. Plan in Phases, Not in Stone

Projects evolve and the plan should too. Stage-gates and milestone reassessments aren't signs of indecision; they’re markers of maturity. Locking in a plan too early and refusing to budge when the unexpected shows up is how small misalignments become massive overruns.

4. Build Contingencies In (and Defend Them Like Crazy)

Buffers aren’t just padding, they’re survival gear. Make them explicit, visible and protected. Then educate every stakeholder on why they exist. Contingency isn't weakness,it’s wisdom that says, “We’ve been here before and this time we’re ready.”

5. Institutionalize Learning

Post-mortems and lessons learned shouldn’t be a checkbox. They should be sacred. Catalog your wins, face your misses and build a reference-class library you can actually use. Institutional memory beats institutional optimism every time.

6. Foster a Culture of Truth

Candor is your construction superpower. Build a culture where people can raise their hand and say, “This isn’t going to plan” without fear of career suicide. The fastest way to kill a project is to kill the messenger. The fastest way to save one is to listen to them.

These aren’t soft skills, they’re survival strategies. The sooner this industry stops pretending that plans are promises and starts treating them as hypotheses to be tested, the sooner we build projects that reflect reality, not fantasy.

Evolve or Repeat: It’s That Simple

Construction doesn’t suffer from poor execution as much as it suffers from poor expectations. The planning fallacy has fooled us into thinking we can tame chaos with control. But in this industry, variation is the constant.

If we want to deliver projects with more confidence, we need to stop pretending the old model works. It doesn’t.

We must embrace a new model. A model that respects variability, learns from history, uses real data and adapts with the project. That’s how we evolve. That’s how we lead. And that’s how we finish what we start on time, with confidence and with far fewer surprises.

The future of construction won’t be built on perfect plans. It will be built on resilient ones.

Construction is cool, tell your friends!