Risk Averse: The Overlooked (and Inevitable) Gift of Failure

Let me say it plainly: failure is one of the greatest teachers we’ll ever have…yet we treat it like an embarrassment.

Especially in construction.

I’ve been in construction for over 20 years. If you were to line up all of my missteps, bad calls, wrong assumptions and good ideas that flopped along the way, you could probably build a decent-sized tower with them. But you know what? That tower would be strong and stable, because it would be built on a foundation reinforced by lessons.

So, yes, we love to celebrate successes in this industry. But often we avoid sharing in the hard truths that almost every win was built on a graveyard of failures. Somewhere along the way, someone tried something, fell short, dissected what went wrong, adjusted the plan and tried again.

And that’s where the magic happens.

Innovation is Fueled by Failure

Take a look at some of the most incredible engineering feats we study in school to this day. Most of them were born from a painful, often catastrophic lesson learned the hard way.

Many have seen the Galloping Gertie videos on YouTube. The Tacoma Narrows Bridge collapsed in 1940, just four months after opening, in a dramatic wind-induced oscillation that looked more like a wave pool than a piece of civil infrastructure. Total disaster? Yes. Engineering embarrassment? Absolutely. But also, a turning point.

Because of that failure, we learned about aeroelastic flutter, something no one had accounted for in suspension bridge design. That one moment in time completely transformed how we engineer bridges. Today, long-span bridges go through rigorous wind tunnel testing, include stiffening trusses and feature aerodynamic decking. All because Gertie couldn’t handle a breeze. Her fall became the foundation for safer, smarter design.

Or how about the lesser-known Hyatt Regency walkway collapse in 1981? It was the deadliest structural failure in U.S. history at the time as 114 people were killed in seconds. The cause? A seemingly minor design change that doubled the load on a support connection…that no one caught.

Out of that tragedy came changes to engineering ethics, stricter protocols for reviewing structural changes and a wake-up call about the importance of communication between the design and construction teams. That failure reshaped how engineers collaborate and has saved lives in the decades since.

And of course I can’t forget about tech. If you’ve been in construction as long as I have, you’ve seen your share of platform rollouts that fell flat. Maybe it was a new-fangled scheduling tool nobody used. Or it could’ve been a shiny out-of-the-box platform that promised connected workflows but delivered total chaos.

Regardless of which, if you did the work…held the postmortem, dug through the reasons it failed, sat down with your users and actually listened…then that failure became fuel. It showed you where the friction lived, what the workflows really needed and what buttons not to push when rolling it out next time.

Failure didn’t kill the idea. It refined it.

Failure Is Feedback (If You’re Willing to Listen)

The problem is most organizations don’t take the time to truly study their failures. We either collect the lessons learned and put them on the shelf or pretend they didn’t happen.

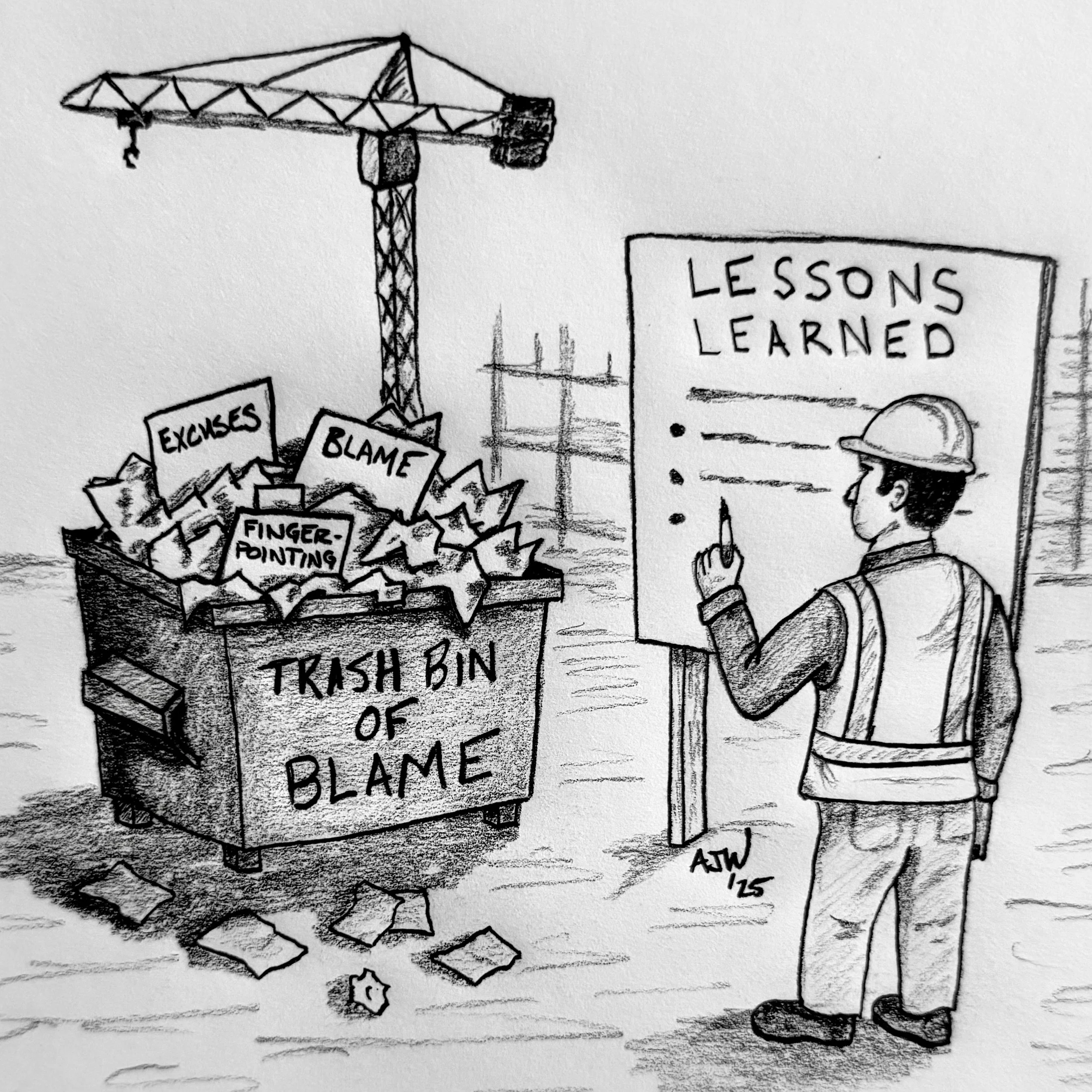

But the definition of insanity is trying the same thing over and over again expecting different results. If you truly want to grow, you have to put your failures under a microscope. Not to assign blame, but to find the friction. To isolate the moment the wheels came off and trace it back to the decision, the assumption or the missed signal that set it in motion.

This mindset, what I often hear called “try, fail, adjust,” isn’t just a slogan. It’s a system. A system that requires intentionality.

So how do you build a culture where failure isn’t feared but rather embraced as a step toward greatness?

Building a “Try, Fail, Adjust” Culture

Normalize Talking About Mistakes

Every team meeting should have room for someone to say, “Here’s what didn’t go right this week.” Leadership included. When senior leaders own their stumbles, it signals that mistakes are part of the process and not career-enders.Do Tactical Forensics, Not Finger-Pointing

When something breaks, resist the urge to ask, “Who messed this up?” Instead ask, “Where did the process break down?” Document the timeline. Interview the team. Find the missing handoff, the unchecked assumption or the tool that didn’t quite fit the job. Treat it like a crime scene investigation, not a witch hunt.Capture and Share “Lessons Unlearned”

It’s not enough to say you learned something. You’ve got to log it, distribute it and bake it into your processes. Consider a “lessons unlearned” database or even a monthly review of failures and fixes across projects. And don’t just share what went wrong, share what you would do differently next time.Prototype and Pressure-Test Ideas

Before you roll out a major change (whether a new workflow, a tech platform or a prefab method) test it in a safe environment. Expect it to break. That’s the point. Better to fail on a small scale with low risk than crash and burn on a flagship project.Reward the Right Kind of Failure

There’s a difference between failing due to negligence and failing because you tried something new. Make that distinction clear. Create space to celebrate bold experimentation, even if the result wasn’t a win. Innovation depends on people knowing they won’t get punished for trying.

Most of All, Don’t Lie to Yourself

The truth is the scoreboard never lies, even though you may think you’re succeeding because nobody’s complaining. But if your project is hemorrhaging margin, rework is creeping up, adoption rates are flat or morale is slipping…you’re simply not winning. You’re surviving.

And surviving isn’t the same as succeeding.

So don’t delude yourself into thinking that just because you didn’t crash and burn, you earned a victory. If you didn’t see improvement in something—quality, safety, efficiency, culture—you probably didn’t win.

But there again, that’s the upside. You’ve got the gift of failure right in front of you. Unwrap it. Dissect it. Learn from it.

And then get back to work. Smarter, sharper and stronger than before.

Construction is cool, tell your friends!